Notifications for Material Certificates

"Deliveries with various certifications are therefore daily business for us," says Boris te Winkel, general manager of Hetraco. "We therefore apply a quality policy that is aimed at continuing to guarantee and control the quality and certification of the product to be delivered."

It was therefore clear to Boris from the start that these material certificates had to be accommodated within MKG. In the past, this was solved in MKG004 using formulas in memo fields, a method that is not possible in MKG5.

"I therefore sat down with MKG consultant Martijn Timmer during the transition to MKG5 to discuss to see whether our wish, no: requirement, to continue working with material certificates in MKG, could be met." That turned out to be possible. Enthusiastic about the solution, Boris explains how Notification Management within MKG works for Hetraco.

The application

A lot is created when a purchase order is entered. Via the purchase packing slip you can immediately go to the lot and there to the 'Notifications' tab. Here the notification type 'Material Certificate', created especially for this purpose, can be selected. In the 'Replies' field, enter the certificate values based on the original certificate that came with the purchase of the material. This is all that needs to be entered. The original certificate is then linked to the lot as a document. A production order can then be created based on the material (always an item). When reserving inventory, the lot is selected and the correct quantities are issued. After production has been reported as ready, the Hetraco certificate - which states the assembly and the values of the linked material certificates entered from Notifications - is generated via the report.

And not only about the solution for storing our own material certificates in MKG, Boris is enthusiastic: "All materials and lots with certificates are visible to me at a glance via the Inventory Dashboard. This way for urgent orders, I can see in real time whether there is sufficient material within a lot with the correct certificate."

Already when creating a bill of materials, specifications and specification codes can be recorded for materials and outsourcing that occur later in the process, at calculations and production orders can be specified. You can also choose to redetermine the specifications based on the currently applicable purchasing price agreements for items.

further

Partner in de spotlight: McMain

proALPHA to expand portfolio with cloud-based ERP for metalworking companies with mainly up to 100 employees.

Borg je eigen processen en afspraken in MKG

Partnerschap tussen People Appy en MKG leidt tot ontwikkeling van nieuwe app voor de metaalindustrie

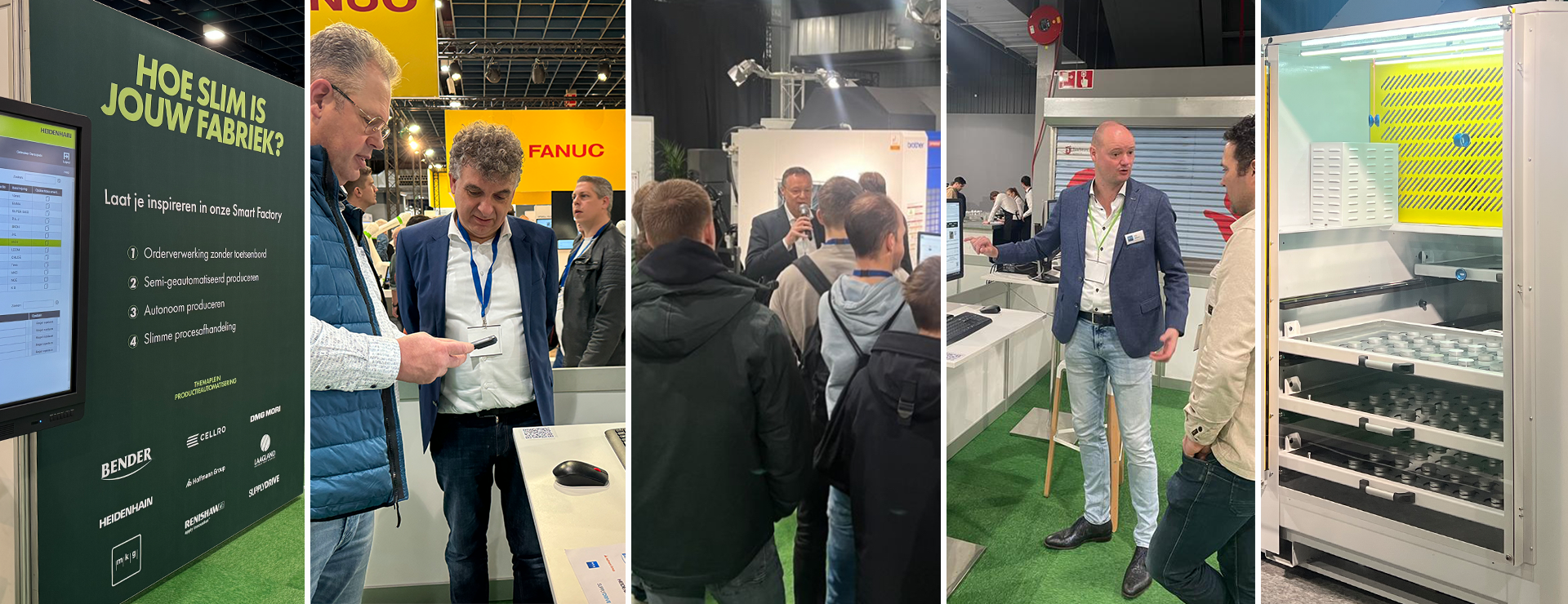

MKG op de Technishow: "Een duidelijk verhaal dat relevant is voor de hele maakindustrie"

MKG Opens Branch on Brainport Industry Campus (BIC)

Review: Optimal Machining in the Digital Factory